Curing resinPH-2055

PH-2055 is a heat-reactive p-tert-octylphenolic curing resin. The major linkage between alkyl phenols in the molecular structure are dimethylene ether (-CH2OCH2-) and methylene (-CH2-). The two terminals of the molecule are mainly sealed with methylol (-CH2OH) or bromomethyl (-CH2Br) active groups. It is especially suitable for vulcanizing natural rubber and various unsaturated rubber. The resin is soluble in solvents such as aromatic hydrocarbons, aliphatic hydrocarbons, ketones, and esters.

Product features:

1. Bromine is introduced into the resin structure, which results in an accelerated vulcanization rate and does not require the introduction of an additional halogen donor.

2. Due to the control of key indicators, the processing safety of the rubber compound is ensured while providing excellent mechanical properties for the final product.

3. This product has a high softening point, which is beneficial to reduce caking during storage and transportation.

Specification

Index Names | Indexes | ||

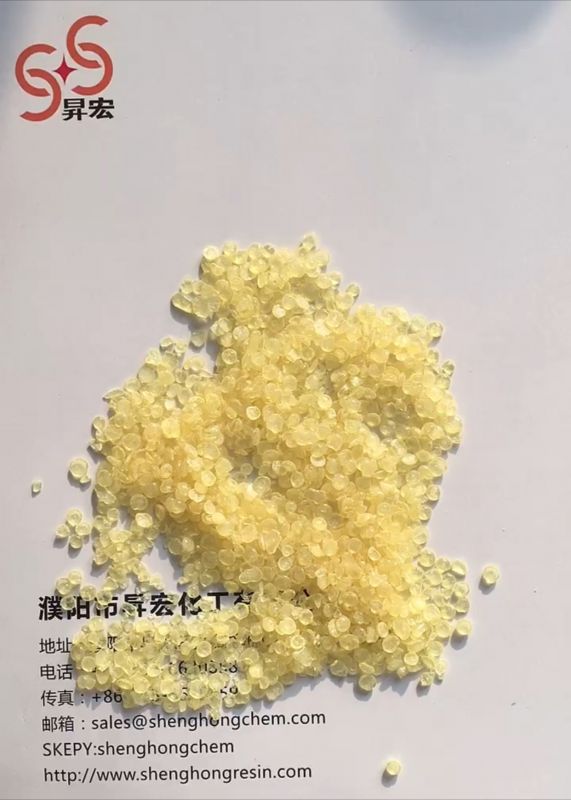

Appearance | Orange-yellow to red-brown flake | ||

Bromine Content ,% | Ⅰ | Ⅱ | Ⅲ(2056) |

3.6-4.0 | 3.8-4.2 | 6.0-7.5 | |

Methylol content ,% | 9.0-12.0 | 9.5-13.0 | 9.5-13.0 |

Softening Point (Ball and ring),℃ | 85-95 | 85-95 | 80-90 |

Packaging:

25KG kraft paper bag

Storage:

Store in a sealed, cool, dry and ventilated environment. High temperatures and excessive stacking can lead to caking.