Product Center

Focusing on the research, development, production, and application of Hydrocarbon resinsApplication Center

Make your product more competitiveShenghong Group was established in 2009, focusing on the fields of adhesives, coatings, rubber, thermoplastic elastomers, new materials, and special materials. After 15 years of development, Shenghong Group has become a fine chemical enterprise that integrates production, learning, research, and application.Since its establishment, the group company has adhered to the business philosophy of "cooperation, win-win, integrity, and development", serving global customers. The company has passed ISO9001:2008 and ISO14001:2004 certifications.After 15 years of business development, the group company's product application areas include sanitary materials, textile materials, rubber materials, industrial anti-corrosion, shipbuilding, aerospace, wind turbine blades, furniture, leather, m

-

2009

The company was established in 2009

-

14

14 years of industry experience, focusing on Hydrocarbon resins

-

1000

Over the years, we have collaborated with over a thousand clients

-

100

With over 100 enterprise employees

News

Focused on the Hydrocarbon resin industry for 14 years-

2023-12-13

2023-12-13Notice on the Extension of the 24th China International Adhesive and Sealant Exhibition

-

2023-12-13

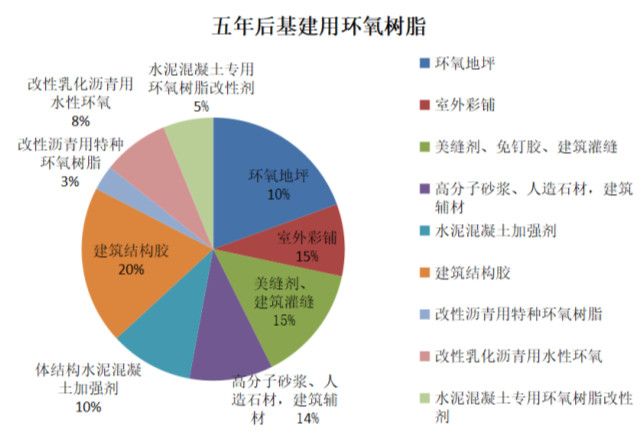

2023-12-13Three major breakthroughs are urgently needed and currently underway in China's epoxy resin for infrastructure construction

-

2023-12-13

2023-12-13The properties and corresponding uses of C5 Hydrocarbon resin

-

2023-12-13

2023-12-13The performance and function of carbon nine Hydrocarbon resin